Results

- 1-click Process Automation

- 10X Speed Improvement

- Watertight 3D Model

- 3D Print Ready

- Optimised Geometry

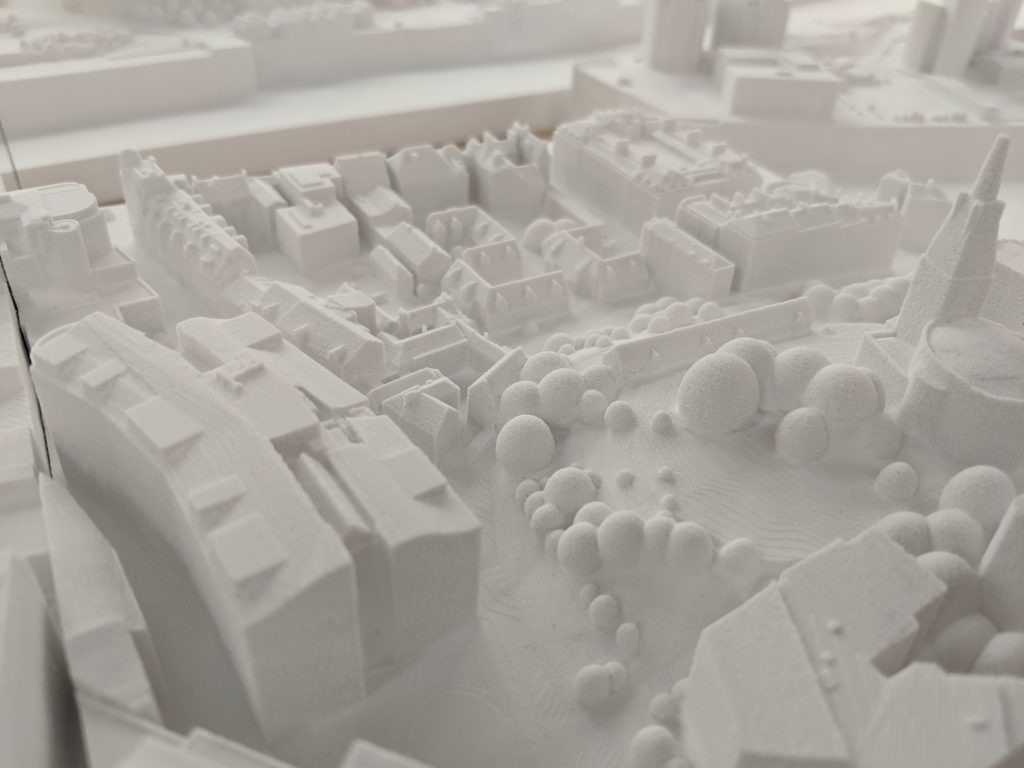

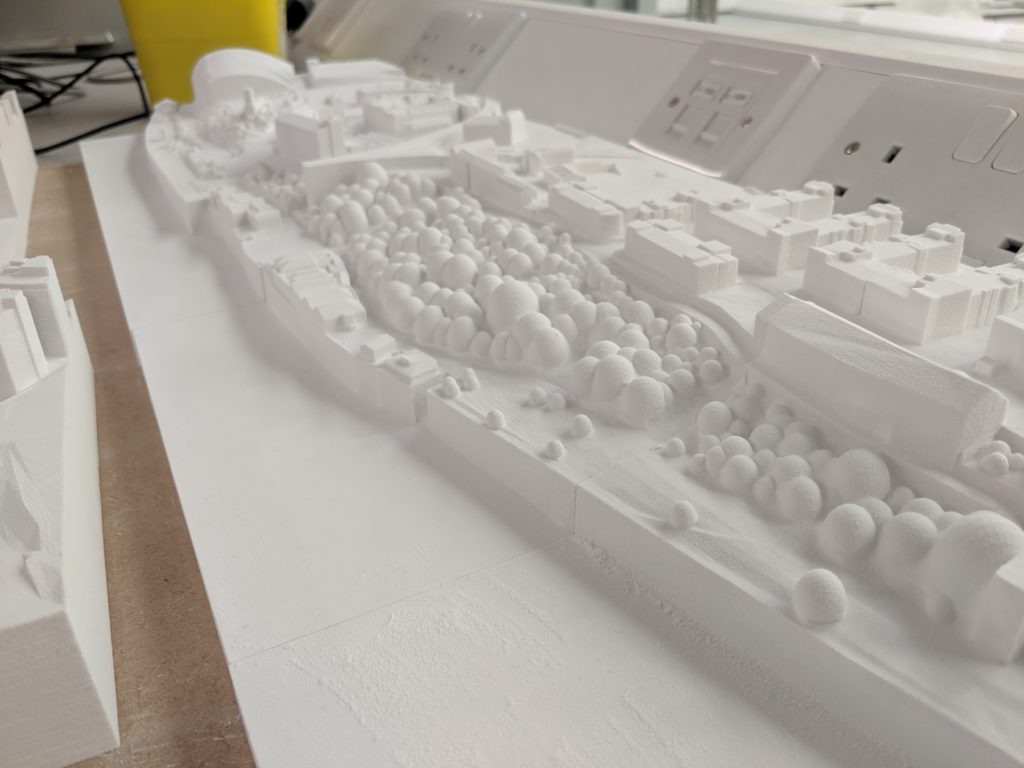

- Accurate 3D Printed Scale Model

- Visualising City Planning

Services

- Process Automation

- 3D Modelling

- 3D Model Optimisation

- 3D Programming

How we used automation to supercharge VRV Studio's 3D city model print pipeline

Project Summary

Challenge

Northumbria University’s VRV Studio needed to prepare their virtual Newcastle-Gateshead city model for large scale 3D printing, on request of the local council. However, the city model needed to be updated to include more recent developments, with modular slots for planned future developments to be inserted.

Outcome

With a thoughtful and skilled approach we successfully automated their previously labour intensive optimisation process, with a 10X efficiency improvement. This enabled us to revamped their city model in a fraction of the time – 1 day instead of 10. Providing them with a highly optimised version of their city model plus all of the existing and planned modular developments.

Impact

The expertly crafted watertight 3D models we produced were able to enter the 3D printing production process much sooner. Giving the client a lead on solving manufacturing issues with printing such a large model. With the process improvements and time savings we provided to their workflow they made huge cost savings in this project. They can continue to use the same 1-click solution.

Leveraging automation in 3D print production

Northumbria University’s VRV Studio is a state of the art campus-based semi-immersive facility run by top academics in Newcastle upon Tyne. A returning client, they approached us to help assist them with the gargantuan task of optimising their virtual Newcastle-Gateshead city model – a highly accurate but data-heavy 3D model generated from an expensive aerial scanning process.

Their end-client, Newcastle Council, had tasked the VRV Studio with 3D printing an up-to-date and modularly expandable city model for use in their city planning activities. However, it would be a major challenge for the VRV Studio, who faced the challenge of needing to take a large 5x5km section of their existing model, updating and remodelling it to be made completely water and structurally supported, ready for 3D printing. The issue was that their current process of manually retopologizing such a large 3D mesh would be expensively resource intensive in terms of time and cost for hiring the required skilled labour. This was on top of needing to model a number of recently erected and planned developments and integrating them into their city model, as well as creating a modular way for future developments to be added in the near future.

This is where our expertise in real-time 3D modelling and process automation was able to benefit the client. We knew that we could use some advanced features of the Autodesk software, as well as write some custom code, that would take similar elements of the model and automate the tasks required based on a list of known variables and repeated steps. Despite a tight timeline of only two weeks we were able to build, test and iterate to create a one-click MEL script solution that we deployed for the client – in only 8 hours!

While our automated solution was handling the previously manual task of optimising the model into a watertight 3D print ready state; we got on with the task of devoting the remainder of the project time before the deadline to modelling the individual 3D models for each of the recent and future developments.

This efficient and effective approach allowed us to extract the most amount of value from the clients project budget. Dedicating precious time on manual tasks that humans are better at than machines, while at the same time leveraging automation and computer processing power to solve tasks that a machine can do faster and cheaper than even the most competitively priced human teams could ever achieve. It’s this “work smarter, not harder” approach that our clients love. Especially when they know that we pass these benefits on to them without any extra charge – it’s all part of our value add.

Combined, our output resulted in exactly what they needed and their end-client was paying for: a structurally sound, watertight, up-to-date and modularly expandable, large-scale 3D model that could now be 3D printed for use in city planning. Proving that with our next-generation approach we could continue to deliver on time and on budget. Meanwhile, traditional and industry standard approaches would have been intensive and error prone; most likely running over time and over budget due to their repetitive, labour intensive and expensive nature.

Northumbria University’s VRV Studio were extremely happy with the outcome and impact, in terms of not just the deliverables (3D models) but also the process efficiency improvements we enabled for them going forward and the immediate and future cost savings we enabled for them. They are now able to optimise any part of their city model data with one-click and no longer require hiring and managing teams of highly-skilled 3D artists over long periods of time.

The finished product is now installed at Newcastle Council and used as intended for accurate and modular city planning.

Understands what the customer requires and gives feedback on the ideas. Their work ethic is excellent and the outputs they’ve created for us are impressive. I have no hesitation to recommend them.